In the context of the rapidly growing culinary and food service industry, investing in industrial kitchen equipment for a canteen […]

Read more

In the restaurant, hotel, or food production business, commercial kitchen design goes beyond aesthetics and functionality—it plays a critical role in the efficiency and safety of the entire operation.

A well-planned commercial kitchen installation, from equipment selection to space layout, can significantly improve productivity, reduce operating time, and save costs.

To achieve this, choosing an experienced kitchen installation consultant is essential. They must have a deep understanding of safety standards, technical requirements, and hygiene regulations to create a complete kitchen system that meets both user needs and official regulations.

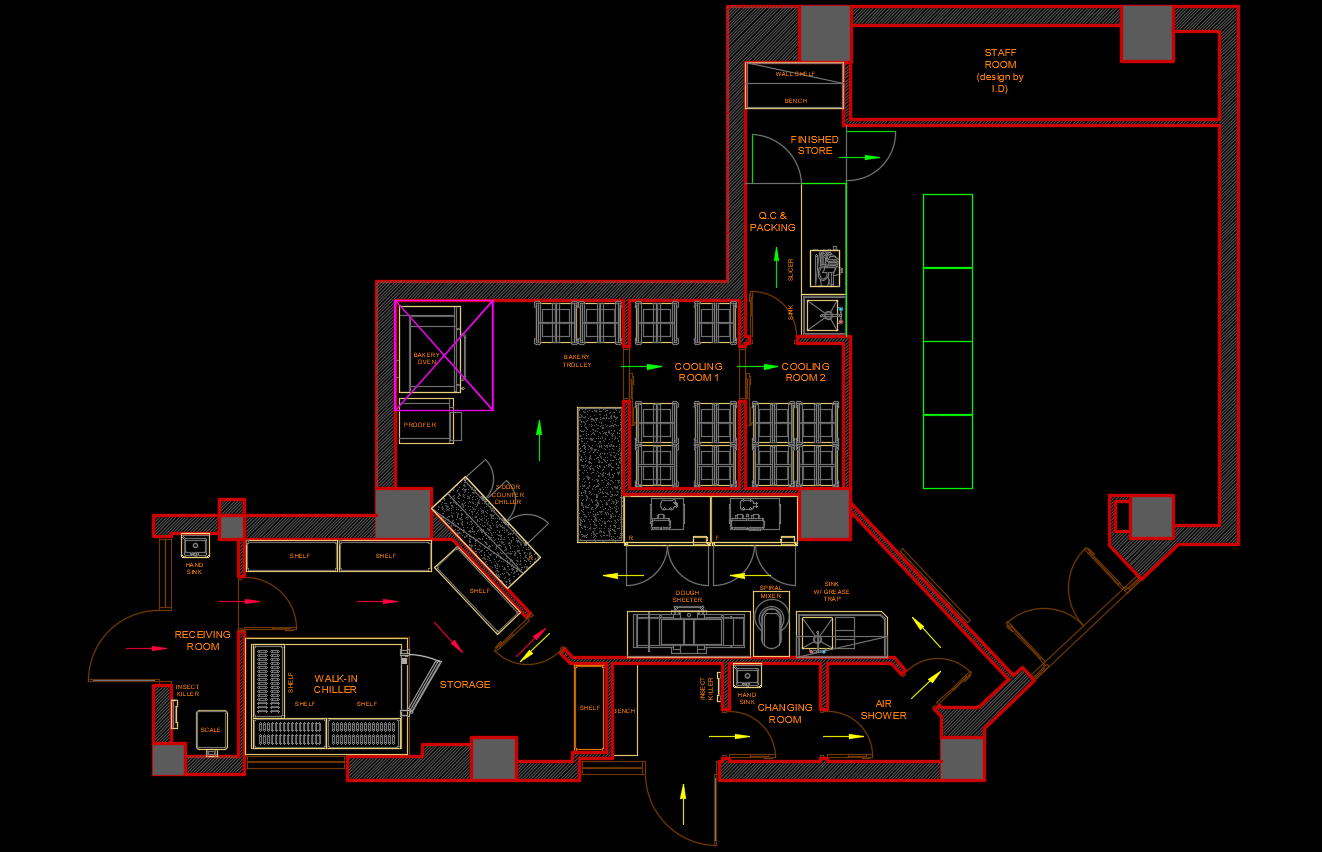

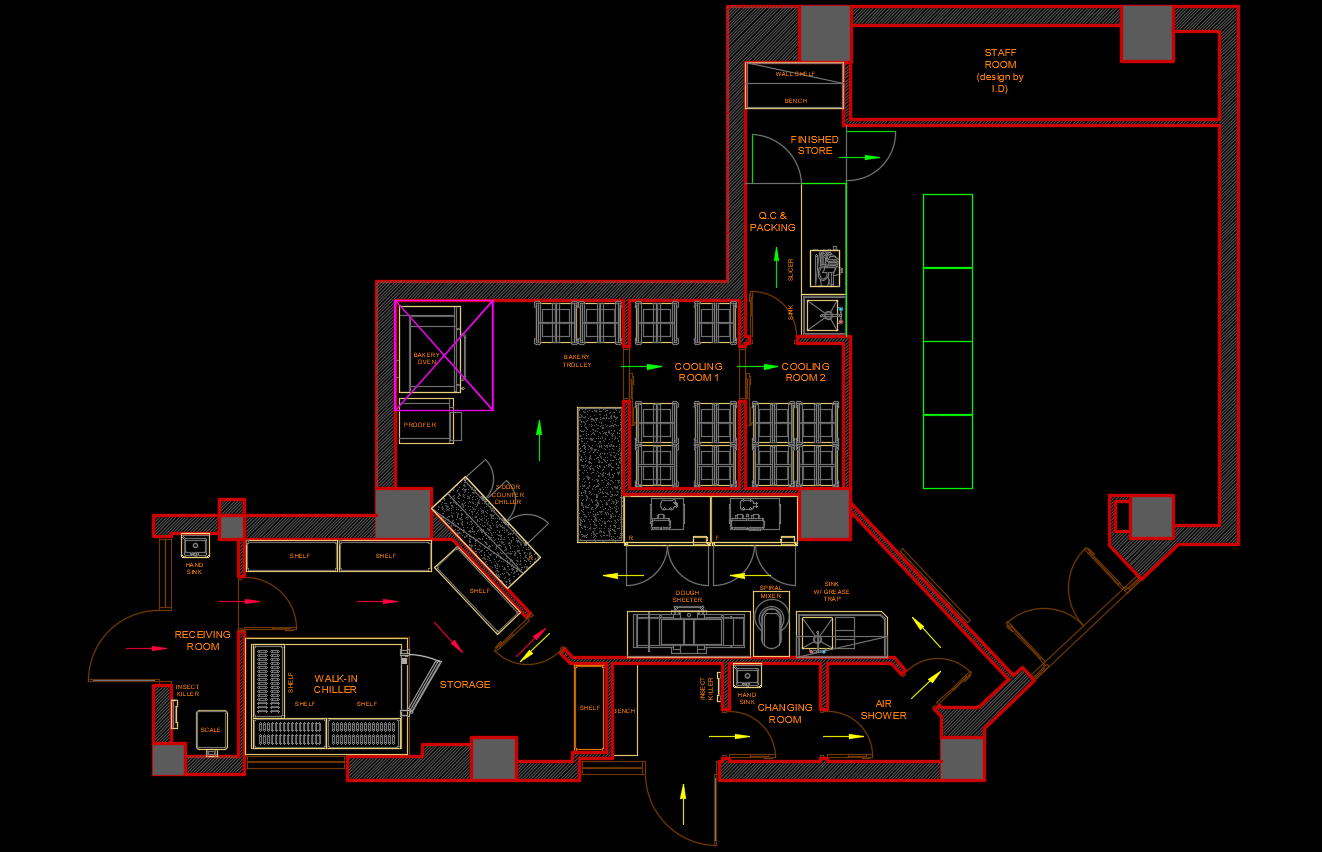

Effective commercial kitchen design starts with clearly identifying the business’s specific needs. The restaurant’s size, type of menu, and the number of customers served daily are key factors that directly influence the kitchen layout and equipment choices.

When planning kitchen installation consulting, thoroughly assessing actual needs helps avoid purchasing excess or insufficient equipment. Additionally, kitchen size should be carefully calculated to optimize workspace, preventing overlapping functions or lack of convenience during high-demand periods.

A professional consulting team will tailor the commercial kitchen installation solutions based on your business model, from selecting the right size and capacity of equipment to designing a layout that ensures smooth workflow between the kitchen’s functional areas.

Each area in the kitchen—from the cooking zone to the washing and food storage areas—must be organized efficiently to ensure seamless operations and flexibility. This not only helps save time and labor but also ensures the safety of staff during work.

An ideal commercial kitchen layout starts with clearly defining functional areas:

Additionally, the kitchen space must be carefully calculated to match the restaurant’s size and needs. A cramped kitchen can hinder movement, while an overly large one might waste space and cause unnecessary travel time.

A well-designed industrial kitchen space ensures a smooth connection between functional areas, optimizing workflow, enhancing productivity, and maintaining safety and hygiene standards.

Selecting the right commercial kitchen equipment is crucial for ensuring efficient and high-quality kitchen operations. Key equipment such as ovens, gas stoves, and industrial refrigerators should be chosen based on the restaurant’s specific needs and technical requirements that align with the available space and scale of operations.

When selecting an oven, consider the menu your restaurant offers. For establishments that specialize in baking or dishes requiring high heat, a convection oven or multifunction oven would be ideal.

Choosing the appropriate stove should be based on capacity and size relative to the kitchen space. High-capacity gas stoves are suitable for restaurants with fast-paced, continuous cooking demands. Additionally, when installing kitchen equipment, it’s essential to focus on safety features like automatic gas shut-off valves to ensure staff safety.

Lastly, the industrial refrigerator should be selected according to the food storage needs. Large-scale restaurants would benefit from high-capacity freezers and coolers with stable cooling systems to keep food fresh for extended periods. Opting for energy-efficient refrigerators is also a smart choice to help minimize operational costs.

To operate a safe kitchen, strict adherence to ventilation, fire safety, and hygiene standards is essential. Proper installation of smoke ventilation and fresh air systems not only eliminates smoke and unpleasant odors but also improves air quality, protecting staff health.

The commercial kitchen ventilation system is a key focus. It must be designed to extract smoke, heat, and grease from cooking areas, ensuring the kitchen remains well-ventilated.

Additionally, the ventilation system must prevent the buildup of these elements to avoid fire hazards and maintain a safe work environment. For added safety and efficiency, it’s advisable to use a ventilation system with a grease filter to reduce the risk of fires caused by grease accumulating in the ducts.

In terms of materials, when installing an commercial kitchen, choosing durable and easy-to-clean materials is crucial. Stainless steel surfaces are often preferred for their ease of cleaning, resistance to stains, and ability to withstand high temperatures and strong cleaning chemicals. These materials not only save time and effort in maintenance but also ensure long-term durability in a harsh kitchen environment.

Lastly, fire safety systems are indispensable. Equipping the kitchen with fire alarms, extinguishers, and automatic fire suppression systems helps minimize risks and protect both property and lives in the event of an emergency.

Controlling costs is crucial when installing an commercial kitchen. Here are some effective ways to save on installation and operational expenses:

These strategies not only help cut costs but also enhance the overall efficiency of your industrial kitchen operations.

With the support of Saigon Horeca’s team of experts, you will receive detailed consultation and tailored solutions for your industrial kitchen system. We are committed to helping you build an efficient, sustainable kitchen that meets the highest standards of the service industry. Contact us today to start optimizing your kitchen space!

Monday - Friday

from 8h00 to 18h00

40 Street No. 6, Melosa Garden, Phu Huu District, HCMC

Contact anytime

In the context of the rapidly growing culinary and food service industry, investing in industrial kitchen equipment for a canteen […]

Read moreLooking to elevate your grilled dishes with a Salamander Grill? With its ability to grill quickly and evenly while giving […]

Read more