Nội dung bài viết Đọc bài viết với ngôn ngữ Tiếng Việt Hệ thống thông gió bếp I. Overview A […]

Read more

- News

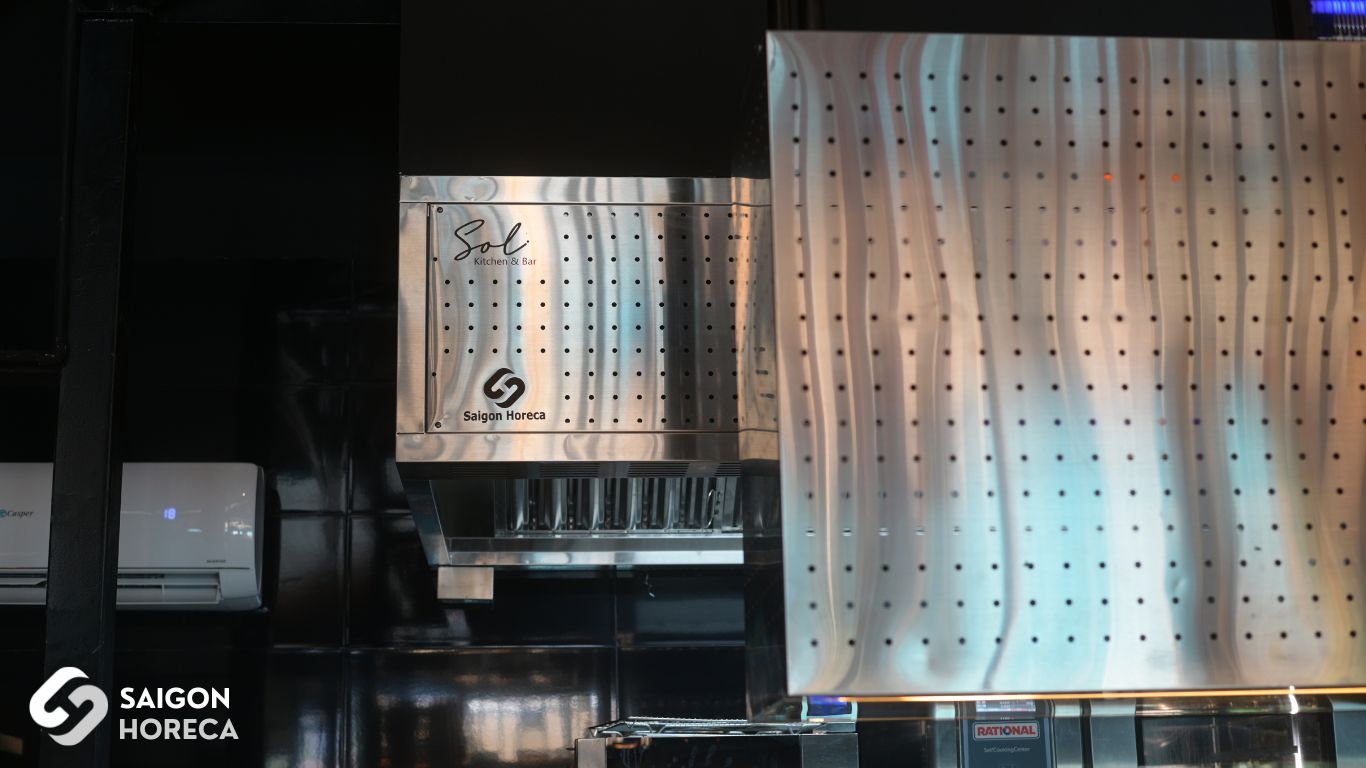

Japanese Teppanyaki Kitchen Design – Saigon Horeca Elevates Your Restaurant Experience

- July 3, 2025

Teppanyaki is a renowned Japanese-style open kitchen concept where chefs not only cook meals but also perform their cooking skills right in front of diners. This unique combination of refined cuisine and culinary performance has made Teppanyaki a signature feature in many high-end restaurants around the world.

In Vietnam, the demand for Teppanyaki-style kitchens is rising, along with higher expectations for equipment quality, technical standards, and aesthetic design. Recognizing this potential and the strict requirements of the concept, Saigon Horeca has partnered strategically with Fujimak Japan – a world-leading industrial kitchen equipment brand with over 70 years of expertise.

The collaboration between Saigon Horeca and Fujimak represents a strong commitment to bringing premium-quality, Japanese-standard Teppanyaki kitchen solutions to the Vietnamese market, meeting international standards in engineering, durability, and operational safety.

In this article

Discover Japanese-Standard Teppanyaki Kitchen Design with Saigon Horeca

To turn a Teppanyaki counter into more than just a cooking station—into a true culinary centerpiece that ensures both high performance and maximum safety—every detail in the design and installation must follow strict standards:

1. Material and Construction Standards

- The cooking surface is made from high-grade stainless steel that is heat-resistant, corrosion-proof, and easy to clean.

- The cooktop is crafted from a single flat steel plate with integrated grease and oil drain grooves around the edges to ensure hygiene and safety.

- The internal frame and structural components are reinforced to handle the heavy-duty operations of a professional kitchen.

2. Technical and Safety Standards

- Teppanyaki grills from Fujimak Japan feature customizable plate thickness (standard: 19mm), optimizing heat retention and temperature stability during cooking.

- Choose between analog or digital temperature control systems for precise operation.

- Integrated wind-shield fans or built-in exhaust systems help contain smoke, heat, odors, and grease, keeping the dining area comfortable and clean.

- Premium models include a built-in automatic fire suppression system, meeting the most stringent fire safety standards.

3. Overall Design Requirements

- The layout must maintain a safe and optimal distance between the cooking zone and diners to balance performance and customer experience.

- Proper planning ensures smooth movement for chefs and service staff, minimizing disruptions during operation.

- The Teppanyaki counter should match the restaurant’s overall interior design, balancing aesthetics and functionality.

4. Saigon Horeca’s Role in Every Project

- Saigon Horeca is not just an equipment supplier — we provide complete consulting and implementation for Teppanyaki kitchen solutions.

- All Teppanyaki equipment distributed and installed by Saigon Horeca comes from Fujimak – Japan’s leading kitchen equipment brand, with over 70 years of experience and a global distribution network.

At Saigon Horeca, we handle everything from consultation to equipment supply, installation, and final setup, following strict technical procedures under the supervision of Fujimak experts. As a result, our Teppanyaki projects always achieve optimal performance and elevate the overall dining experience.

Featured Teppanyaki Grill Models Installed by Saigon Horeca

All Teppanyaki grills provided and installed by Saigon Horeca (SGH) are manufactured in Japan by Fujimak, a globally trusted brand in premium commercial kitchen equipment.

To meet the specific operational needs of different restaurant concepts, Saigon Horeca collaborates with Fujimak Japan to develop a wide range of specialized Teppanyaki grill models—each designed to meet strict requirements for technical performance, safety, and aesthetics.

Below are three standout solutions currently offered by Saigon Horeca in the Vietnamese market:

Teppanyaki Grill with Built-in Ventilation System (Griddle With Ducts)

An ideal solution for locations where ceiling-mounted exhaust systems are not feasible—such as restaurants in shopping malls, upper floors, or open spaces.

- Internal ducting and exhaust fans are fully integrated into the body of the grill, connected to a remote fan system to reduce noise levels.

- Equipped with a low-noise motor, ensuring quiet operation that preserves the dining atmosphere.

- Enclosed design protects internal components, simplifies maintenance, and ensures long-term safety.

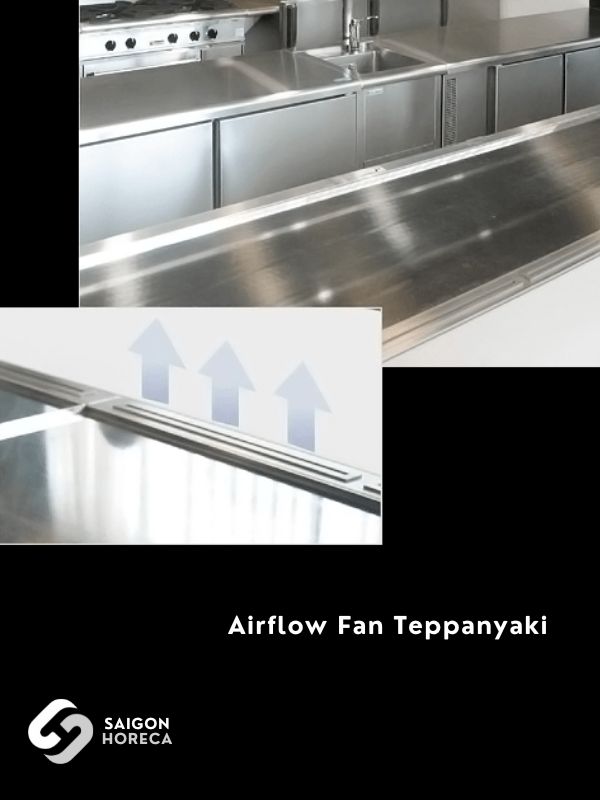

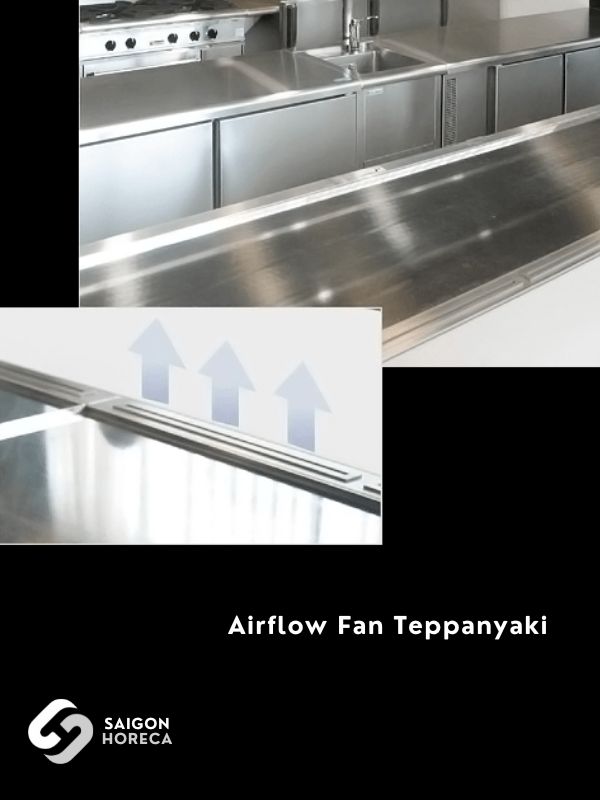

Teppanyaki Grill with Airflow Fan (Airflow Fan Teppanyaki)

One of the most premium options available, this design creates an air curtain between the cooking surface and the guest seating area.

- Effectively blocks smoke, heat, and grease splatter, keeping the dining area clean.

- Enhances safety and comfort for diners during the meal.

- Maintains the clean, open-kitchen look, minimizes odors—perfect for fine dining restaurants.

Teppanyaki Grill Mounted on Refrigerated Cabinet or Integrated Counter (Countertop Teppanyaki)

A space-saving and multi-functional solution ideal for compact kitchens or restaurants that need to combine multiple prep areas in one setup.

- The grill is designed to be installed directly on top of an undercounter refrigerator, prep cabinet, or stainless steel counter, reducing footprint and construction costs.

- Improves workflow by keeping ingredients immediately accessible underneath, allowing chefs to work faster and more efficiently.

- Ideal for hybrid setups like Teppanyaki with sushi bars, izakaya, or restaurants with high-volume service.

Depending on your floor plan and operational model, Saigon Horeca’s expert team will recommend the most suitable Teppanyaki solution and support the overall kitchen layout design—ensuring a perfect balance between functionality, safety, and guest experience.

Key Principles in Professional Teppanyaki Kitchen Design

To ensure safety, functionality, and aesthetics, the design and installation of a Teppanyaki kitchen must strictly follow technical guidelines. With extensive experience in premium open-kitchen projects, Saigon Horeca adheres to the following essential principles:

1. Compliance with Fire Safety Standards

Teppanyaki grills operate at high temperatures and often include live-fire cooking demonstrations, making fire safety an absolute requirement.

The kitchen system must be equipped with dedicated fire protection devices, such as automatic gas shut-off valves, heat sensors, and integrated fire suppression nozzles (available on high-end models from Fujimak).

All materials and equipment used must be fire-resistant and able to withstand high heat.

2. Optimized Movement Flow for Chefs and Guests

Chef workstations should be laid out for maximum convenience and safety, minimizing collisions during peak hours.

Guest seating areas should be clearly separated and safely distanced to ensure a smooth and comfortable dining experience during live cooking.

3. Use of Industrial-Grade Materials

Surfaces around the grill—including the cooktop, counters, and surrounding zones—must be made from high-grade stainless steel, which is heat-resistant, corrosion-proof, and easy to clean.

For the grill plate itself, Fujimak standards require a solid steel surface with a minimum thickness of 19mm, which helps maintain stable temperatures and extends the product’s lifespan.

4. Proper Distance Between Grill and Guest Seating

According to international standards, the distance between the edge of the grill and the guest seating must be scientifically calculated to ensure both operational safety and optimal viewing of the cooking performance.

Especially with models that feature integrated airflow fans or internal exhaust systems from Fujimak, the surrounding space remains clean, odor-free, and smoke-free.

With hands-on experience from numerous high-end projects and close collaboration with Japanese experts, Saigon Horeca is committed to delivering Teppanyaki kitchen solutions that meet global standards, maximize performance, and ensure absolute safety in every installation.

Saigon Horeca’s Teppanyaki Kitchen Implementation Process

To ensure that every Teppanyaki kitchen system delivers optimal performance while fully complying with strict Japanese and international technical standards, Saigon Horeca (SGH) follows a standardized, professional process, developed through a strategic partnership with Fujimak Japan. The steps include:

Step 1: Collecting Requirements & Site Inspection

- Saigon Horeca’s technical team works directly with the investor to understand the restaurant’s concept, usage needs, and specific requirements for the show kitchen area.

- A thorough on-site survey is conducted to assess existing infrastructure, including electrical systems, water supply, ventilation, floor and ceiling structure, etc.

Step 2: Proposing the Optimal Solution Based on Real-World Experience

Based on the site survey and project characteristics, Saigon Horeca provides a comprehensive solution, including:

- Recommending the most suitable Teppanyaki grill model (e.g., built-in exhaust, wind-shield fan, countertop-mounted unit)

- Analyzing layout options to optimize space and improve workflow

Step 3: Collaborating with Fujimak Experts to Finalize Detailed Design

- All design proposals are closely coordinated and reviewed with technical experts from Fujimak Japan.

- Detailed 2D layouts, 3D perspectives, and system drawings are completed to ensure technical precision, functionality, and visual harmony.

Step 4: Fabrication and Manufacturing at Fujimak’s Factory in Japan

- All Teppanyaki equipment is custom-manufactured at Fujimak’s factory according to the agreed specifications.

- The production process strictly follows international standards for quality, durability, and safety.

Step 5: Delivery and Installation by Saigon Horeca, Supervised by Fujimak Experts

- Upon completion, the equipment is shipped to Vietnam with proper handling to ensure safety in transit.

- Saigon Horeca’s highly skilled installation team handles the on-site setup.

- The entire installation is supervised by Fujimak’s Japanese technicians, ensuring every component is installed to Japanese technical standards.

With a structured and synchronized workflow, and close cooperation with international partners, Saigon Horeca is committed to delivering high-quality Teppanyaki kitchen projects that operate reliably over time and elevate the prestige of any dining space.

Choose Saigon Horeca – Choose Long-Term Value

With over 10 years of experience and a strong partnership with Fujimak Japan, Saigon Horeca is proud to be a trusted partner in Vietnam, delivering and implementing Japanese-standard Teppanyaki kitchen systems. Every project is executed with technical precision, visual appeal, and operational efficiency.

Backed by a team of experienced engineers with deep knowledge of commercial kitchen equipment, Saigon Horeca is committed to providing tailored kitchen solutions that match the specific space and requirements of each project—ensuring both functionality and long-term value.

Thứ hai - Thứ sáu

từ 8h00 đến 18h00

Số 40 Đường số 6, KDC Melosa Khang Điền, Phú Hữu, HCM.

Liên hệ ngay

Looking to elevate your grilled dishes with a Salamander Grill? With its ability to grill quickly and evenly while giving […]

Read more