An Overview of Cooking & Chilling Systems:

Cooking & Chilling Systems is a reliable and efficient solution for professional restaurants and kitchens.

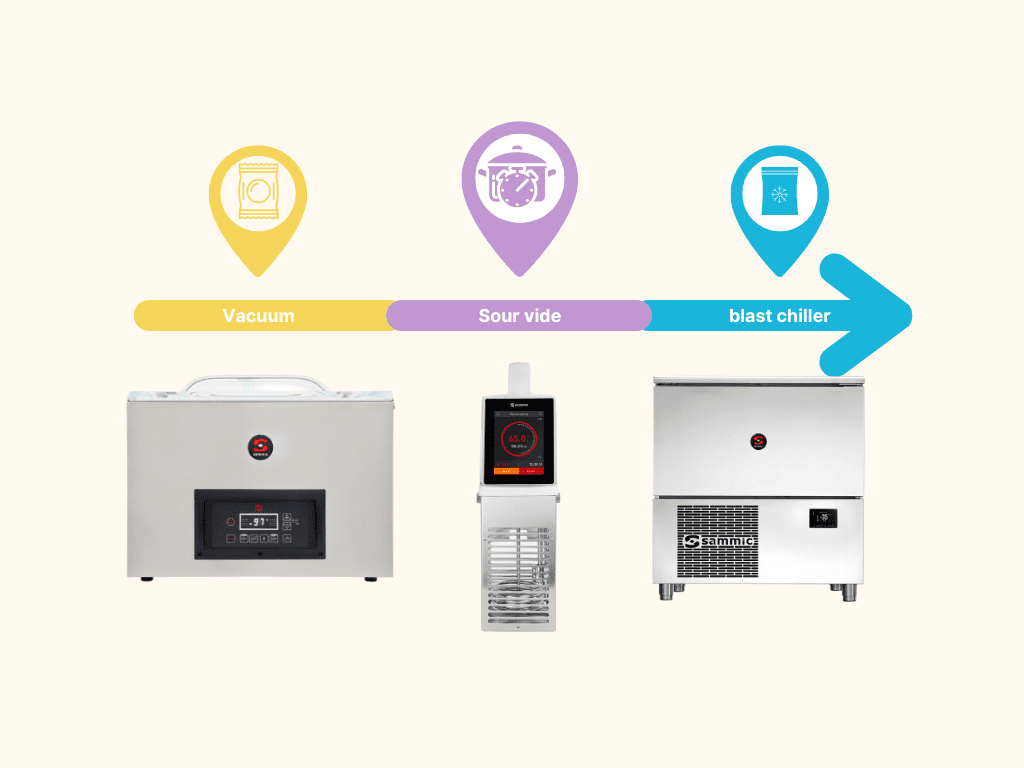

It includes a lot of equipment that constitutes a professional system but a basic and complete mix includes:

It comprises three essential components: vacuum packing machines, slow cookers, and rapid freezing machines, optimizing workflow and enhancing work processes while ensuring that the food remains consistently fresh and flavorful.

Vacuum Packing Machines: Designed with advanced technology, these machines enhance the food’s durability and preserve its natural flavors. By eliminating air and moisture during food storage, they prevent oxidation and spoilage, prolonging the food’s shelf life while retaining the exquisite taste that chefs want to convey to their customers.

Slow Cookers: A crucial tool in the professional kitchen, slow cookers allow chefs to prepare tender, delectable, and nutritious dishes. With precise temperature control, slow cooking ensures even cooking of meats and vegetables, preserving their flavors and nutrients, resulting in dishes that customers love.

Rapid Freezing Machines: For restaurants and professional kitchens, rapid freezing machines play a vital role. Significantly reducing thawing time, they enhance work efficiency and streamline processes. The rapid freezing system maintains food quality, preventing color and flavor loss while ensuring food safety and hygiene.

If you are a customer seeking to optimize your processes and ensure the freshness of your products, the following information is essential to read.

Compare the performance of system application and non-system application in the kitchen:

Cooking& Chilling Systems | Traditional | |

Processing Time | Reduce processing time for ingredients with slow cooking and fast chilling features | More time-consuming in the cooking and chilling process. |

Storage Preservation | Use vacuum packers to preserve food quality and extend shelf life. | Encounter difficulties in preserving and storing ingredients. |

Food Quality | Ensure dishes are fresh, maintain their natural flavor and nutrition. | May face challenges in maintaining food quality. |

Investment Cost | Requires an initial investment with long-term benefits. | No initial investment cost, but may encounter difficulties in maintaining quality and productivity. |

Research Figures:

- Processing Time: Using Cooking & Chilling Systems reduces ingredient processing time by up to 40% compared to not using the system.

- Storage Preservation: The vacuum packing system extends ingredient preservation time up to 5 times compared to traditional methods.

- Food Quality: Over 90% of customers expressed satisfaction with food quality after using Cooking & Chilling Systems.

- Productivity: The capacity of the cooking and chilling process increases by 30% when using slow cookers and rapid chillers.

- Cost Savings: On average, there is a 15% reduction in overall costs in the cooking and chilling process due to the application of Cooking & Chilling Systems.

Note: The figures and data mentioned above are based on calculations and statistics from real-world research and may vary depending on the conditions and processes of each restaurant.

Saigon Horeca is currently stocking all the equipment in the F&B industry that you need.

Vacuum Packing Machines:

-

Vacuum Sealer

Vacuum sealer SU-520CC – Sammic

-

Vacuum Sealer

Vacuum sealer SU-420 – Sammic

-

Vacuum Sealer

Vacuum Sealer SU-416 – Sammic

-

Vacuum Sealer

Vacuum sealer SU-316 – Sammic

Sous-vide machine:

Blast chiller:

+84 901 304 365

Monday - Friday from 8am - 6pm

Ho Chi Minh City, Vietnam

40 Street No. 6, Melosa Garden, Phu Huu District, HCMC

contact@saigonhoreca.com

Contact me every time!