2024 marks a significant milestone for Vietnamese cuisine as more...

Read More

- Kitchen Equipment by Business Model

Structure and Operation of the Multi-functional Baking Oven: Professional Baking Equipment

- November 23, 2023

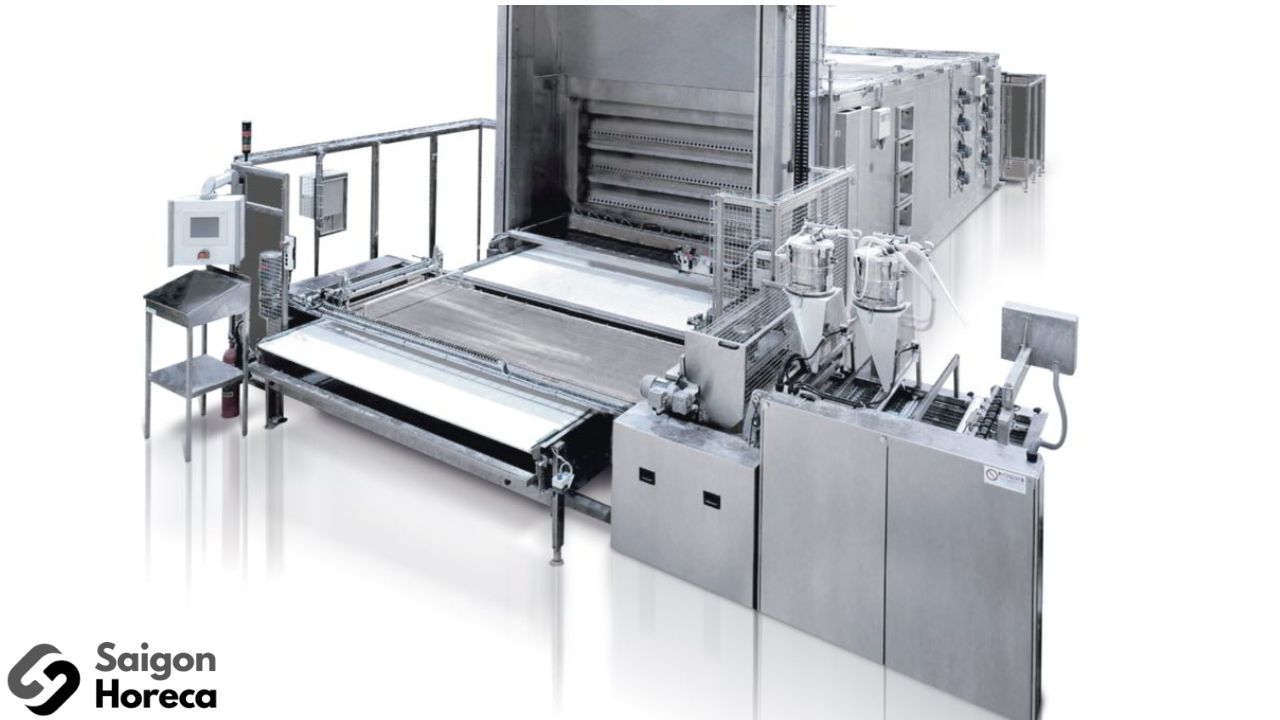

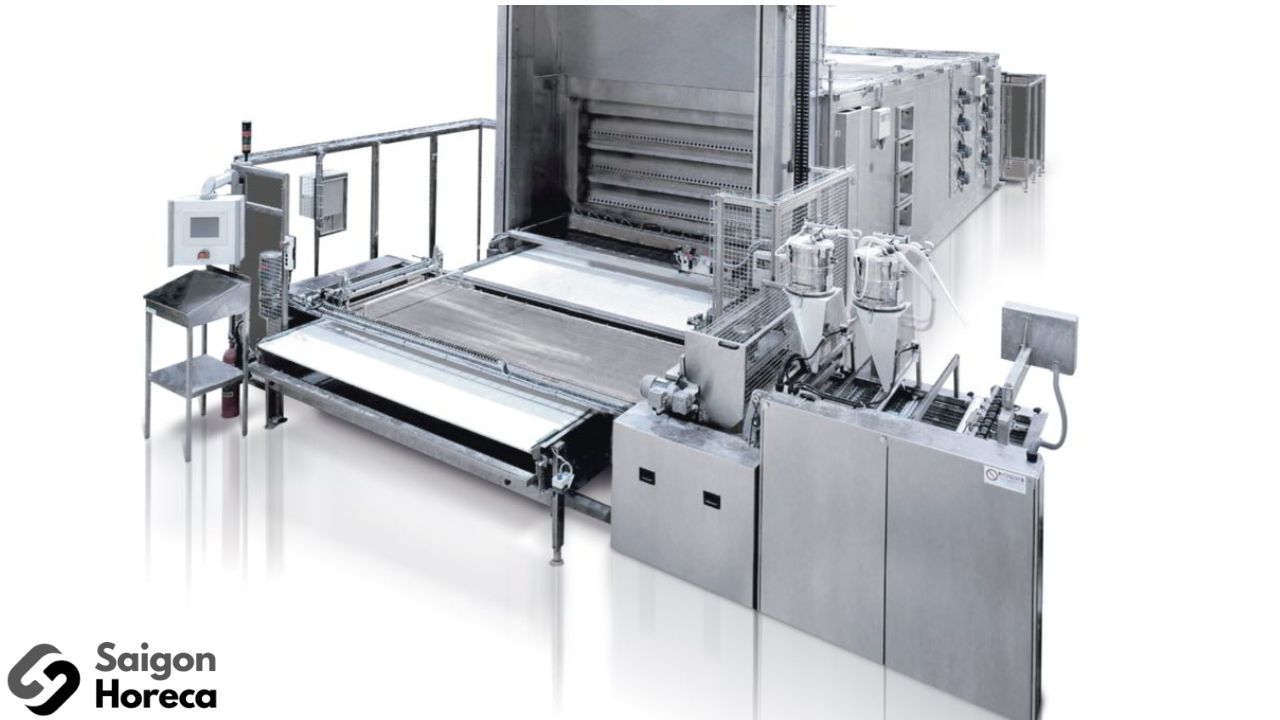

Sweet cakes, bread, sponge cakes, and various other types of pastries are indispensable delights in the daily lives of people. But have you ever wondered about the mass production process of these delicious treats? That’s where industrial baking ovens play an incredibly crucial role.

In reality, not everyone is familiar with industrial baking ovens and their decisive role in the mass production of baked goods. In this article, we will delve deeper into industrial baking ovens, exploring how they function and the benefits they bring to the food industry. Let’s discover the advanced technology behind baking and the significant contribution of baking ovens in the industrial baking process.

In this article

What is a Baking Oven?

A baking oven, commonly used in the food industry, plays a crucial role in the pastry production process. It is where the baking and cooking of bread, sweet cakes, sponge cakes, and many other pastry products take place. The baking oven is designed to create a stable temperature environment and control the temperature over time, ensuring that the pastries are baked evenly and deliciously from the inside out.

An integral part of this equipment is the automatic temperature control system. This system ensures that the temperature inside the oven always meets the requirements of the production formula, resulting in pastries with distinctive flavor and crispiness.

Moreover, baking ovens are often made from rust-resistant materials such as stainless steel to ensure durability and hygiene. The ventilation fan system helps distribute heat evenly within the oven, ensuring that each layer of baked goods is perfectly done.

Food manufacturers and bakeries use baking ovens to ensure that the final products meet quality standards and the delectable taste that customers expect.

Structure and Operation of the Professional Baking Oven

Baking Oven Structure

Regardless of the type of industrial this equipment, they are all designed in a vertical rectangular box shape, an efficient design that maximizes production space, allowing users to arrange multiple baking trays efficiently in a limited space.

- The entire baking oven is constructed from premium stainless steel, a heat-resistant material that is corrosion-resistant and durable over time.

- The structure of the baking oven is often thick, and it includes a layer of glass wool insulation to minimize heat loss to the outside.

- The oven door is typically equipped with a sturdy handle and a secure latch, ensuring it does not come loose or open during operation. The contact area between the oven door and the oven chamber is sealed with a tight rubber gasket, preventing hot air from escaping and ensuring a stable temperature inside the oven.

- Industrial bread ovens often use wave-shaped baking trays made of rust-resistant stainless steel, ensuring food safety and hygiene. There are two common tray sizes: 40 x 60 cm and 46 x 72 cm.

- The control panel of the baking oven is usually located on the left side of the oven door for convenient use. The intelligent control panel includes temperature adjustment knobs ranging from 0 to 400 degrees Celsius, a timer for baking and misting time, a power switch, and clearly labeled indicator lights. This allows users to easily and efficiently control the baking process.

Operation of the Baking Oven

This equipment is a crucial device in the baking and food industry. Its primary function is to create a controlled temperature environment for baking cakes and food items. The oven operates by preheating to the desired temperature set on the control panel. The intelligent temperature control system ensures a consistent temperature throughout the baking process. The timer function allows users to set precise baking times for different types of pastries. Temperature control is a vital part of the baking process, and the control panel on the oven allows users to set their desired temperature. The oven will automatically adjust the heat source to achieve and maintain this temperature.

Wave-shaped baking trays are filled with a mixture of pastry, and then the trays are placed inside the oven. The even distribution of heat, assisted by the ventilation fan system, ensures each layer of pastries is perfectly baked. A sealed door and insulation contribute to energy efficiency by retaining heat within the oven.

Some ovens also feature a humidifying mist function to keep the food adequately moist during baking. The baking time can be set on the control panel, and the oven will automatically shut off when the set time elapses.

In summary, the combination of sturdy construction, advanced temperature control, and meticulous design makes the professional baking oven an essential tool in the efficient and high-quality production of various baked goods.

Why a Multi-functional Steam Baking Oven is the Optimal Solution for Restaurants?

The multi-functional steam this equipment is the optimal choice for restaurants, offering numerous advantages. Firstly, this oven has a large serving capacity and helps save space in the kitchen. With its compact design, it is suitable for any kitchen space and can replace various appliances such as ovens, stoves, fryers, and grills.

Here are some reasons why the multi-functional steam baking oven has become the top choice for restaurants:

1. Space Efficiency

In the limited space of a restaurant, using multiple kitchen appliances can lead to clutter and loss of precious space. The multi-functional steam this equipment is designed to be compact and flexible, saving space and allowing for optimal use of the kitchen area. With dimensions of 937x821x715 mm, it can easily integrate into any kitchen setup.

2. Labor Efficiency

Using multiple small appliances requires a significant workforce to operate and manage. In contrast, the multi-functional steam this equipment only requires one operator, reducing labor costs and optimizing work efficiency in the kitchen. This also increases the capacity to serve customers, helping the restaurant maximize revenue.

3. Cost-Effective Operation

The multi-functional steam baking oven is designed with advanced technology, saving fuel and energy. The cooking time is significantly reduced, helping cut operational costs. This not only saves money but also benefits the environment by reducing fuel consumption.

4. Versatility in Food Preparation

The multi-functional steam baking oven offers a range of cooking methods such as baking, roasting, steaming, grilling, braising, boiling, simmering, baking cakes, and even the slow-cooking method Sous Vide. This allows chefs to prepare multiple dishes simultaneously without worrying about flavors and colors mixing. The dishes retain their original flavors and characteristics, making the menu diverse and appealing.

In summary, the multi-functional steam baking oven not only saves space, labor, and operational costs but also provides flexibility in food preparation. It is truly an optimal solution for restaurants and hotels looking to streamline kitchen operations and enhance the quality of dishes.

The Essential Principles of Baking and Why Berjaya Baking Ovens Stand Out

Why is this equipment considered the superior choice, and how does it address common issues in the baking process?

Firstly, let’s explore some common situations encountered when baking with conventional ovens. You’ve likely faced at least one of the following scenarios:

- Cakes rise and crack, the surface shows signs of over-browning, but the inside remains moist and sticky.

- Normally risen cakes, beautifully golden on the outside, collapse, shrink, or wrinkle after being taken out of the oven, with a slightly damp and possibly eggy odor inside.

- Pale, dry, and thick outer layers with a dense, moist, and sticky interior.

These issues often stem from various factors, including errors in the baking recipe, the baking process, and the baker’s experience. However, a crucial factor is understanding this equipment itself. This raises the question: Why does the Berjaya baking oven excel?

The Berjaya oven is not just a device; it’s a reliable tool, a significant companion in the baking journey. With a tight design and top-notch technological knowledge, the Berjaya oven helps you perfect temperature control, baking time, and tray positioning. This ensures that your cakes are always baked evenly and delicious.

Furthermore, the Berjaya oven is crafted from high-grade stainless steel, excelling in heat resistance, rust resistance, and long-term durability. The sturdy construction and glass wool insulation layer prevent heat loss, ensuring fast baking and energy efficiency. The oven door, with a robust handle and secure latch, maintains stable internal temperatures, preventing cakes from collapsing or shrinking after baking.

With the smart control panel, you can easily adjust temperature, baking time, and misting time. All of these features help you create perfect cakes, eliminating worries about common baking issues.

In conclusion, the Berjaya baking oven not only provides effective temperature control and energy efficiency but also offers durability and ease of use. It is indeed the optimal solution for bakers seeking reliable and high-quality baking equipment.

>>> To understand the necessary steps to initiate and grow a successful and delicious bakery business, read on to begin your entrepreneurial journey: 9 Essential Steps When Opening a Bakery: A Detailed Guide for a Successful Business.

Monday - Friday

from 8h00 to 18h00

Số 40 Đường số 6, KDC Melosa Khang Điền, Phú Hữu, HCM.

Contact anytime

In the modern context, a canteen kitchen is not just...

Read More