Looking to elevate your grilled dishes with a Salamander Grill?...

Read More

- Industrial Kitchen Equipment, Inox Kitchen Equipment

Stainless Steel 201 (Inox 201): Pros and Cons in Practical Use

- November 16, 2023

Known as an innovative solution in the stainless steel industry, Stainless Steel 201 is attracting significant attention. Its appeal goes beyond just excellent durability and corrosion resistance; it also stems from its versatility in manufacturing and widespread use. In this article, Saigon Horeca will explore the details of Inox 201, from its chemical composition to the intriguing applications it offers. Let’s delve into this highly informative material about the substance and understand why Inox 201 is increasingly favored in various fields.

In this article

What is Stainless Steel 201 (Inox 201)?

Inox, a renowned type of stainless steel, is known for its durability and excellent corrosion resistance. The quality of inox depends on adjusting its chemical composition, with one of the crucial factors being nickel. Nickel plays a pivotal role that cannot be replaced, deeply influencing the corrosion resistance, hardness, and durability of inox.

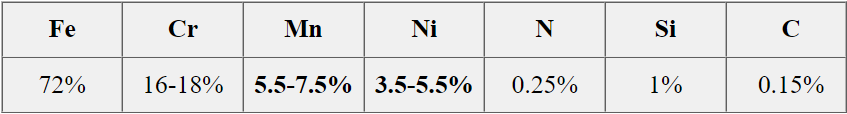

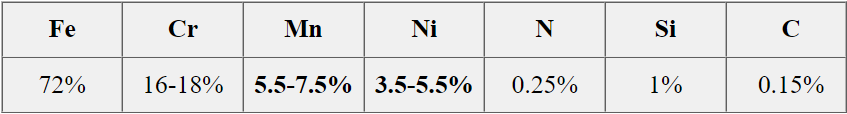

However, in recent times, the soaring price of nickel has posed many challenges to the stainless steel industry. To address this issue, Inox 201 has emerged. It has a modified chemical composition compared to traditional inox. The nickel content has been reduced and replaced by nitrogen and manganese. The chemical composition of stainless steel 201 includes approximately 72% iron, 18% chromium, 6% manganese, 3% nickel, and small amounts of other elements.

This change in the chemical composition of Inox 201 demonstrates the industry’s innovation and efforts to find solutions in the context of rising nickel prices. It exemplifies the diversity and flexibility in manufacturing stainless materials, meeting the diverse requirements of various applications.

Currently, Stainless Steel 201 has become a versatile material that can be processed in many different forms. It can be easily bent, cut, and welded, making it suitable for the production of various parts and products. Stainless Steel 201 is particularly popular in the manufacturing of household items, such as cookware and interior decorations. It is also used in the production of various products, including solar water heaters and many other applications. The success of it reflects the diversity and flexibility of the stainless steel industry in creating alternative and resource-saving solutions in the face of valuable raw material shortages like nickel.

The main chemical components of Inox 201

Characteristics of Inox 201

Durability and Processability

Stainless Steel 201 is a versatile material that stands out with most of the basic properties expected from stainless steel. Not only is it a mirror-like, smooth, and durable material, but Stainless Steel 201 also excels in corrosion resistance and remarkable heat resistance. However, due to differences in chemical composition compared to other stainless steel types, some of these properties show minor variations.

A specific example is the hardness and corrosion resistance of Inox 201. Due to lower nickel content, Inox 201 has lower hardness and corrosion resistance compared to Inox 304, a traditional stainless steel type.

The density of Inox 201 is 7.93 g/cm3, similar to Inox 304, indicating stability in design. Especially, Inox 201 can be shaped well, easily processed through methods like welding or cutting, making it a preferred choice in the household goods manufacturing industry.

Although it has low magnetic properties and only lightly attracts magnets, when annealed, Inox 201 exhibits strong magnetic properties. It also demonstrates characteristic durability and reliable heat resistance, especially in humid conditions. However, it’s important to note that Inox 201 can experience mild corrosion from high levels of acid and salt.

With a lifespan of approximately 15 to 20 years of use, Inox 201 is considered a sustainable solution for various applications. Its flexibility in usage and adaptability to different environments makes Inox 201 a popular choice in many industries.

Corrosion Resistance

The corrosion resistance of Inox 201 is often influenced by several crucial factors in its chemical composition.

Firstly, Inox 201 has a lower chromium content compared to Inox 304, approximately only 2%. Chromium is an essential component for creating a surface oxide layer, protecting steel from corrosion. Due to less chromium, Inox 201 tends to have lower corrosion resistance than Inox 304, especially in environments with acid or salt.

Secondly, Inox 201 also has a lower sulfur content than Inox 304. Sulfur can affect the surface corrosion resistance of metal. Therefore, with less sulfur, Inox 201 may have lower surface corrosion resistance than Inox 304.

However, this doesn’t imply that Inox 201 is without value or cannot be used in applications requiring corrosion resistance. Inox 201 still has corrosion resistance, and it can be chosen for specific applications based on specific requirements and conditions.

Is Inox 201 Toxic?

Inox 201 does not contain toxic substances and does not have elements harmful to human health. This is a significant advantage of stainless steel in general and Inox 201 in particular. It is a health-safe material and environmentally friendly. There is no risk of toxicity when using Inox 201 or products made from it. Therefore, you can use Inox 201 with peace of mind in various applications without worrying about toxicity.

Inox 201 is a safe and non-toxic material for use in most applications. However, there are some limitations and specific restrictions related to using Inox 201 in acidic environments.

One point to note is that Inox 201 contains a certain amount of manganese and some types of metals in its chemical composition. In acidic environments, such as fruit juice extraction, manganese can leach into food or beverages. This can cause health issues if exposed to high levels of manganese, such as affecting the nervous system, causing kidney toxicity, lung issues, or cardiovascular problems.

Therefore, avoiding the use of Inox 201 in applications related to acidic food or beverages is a safe and recommended choice. Instead, it’s advisable to use Inox 304 or other stainless steel types with better corrosion resistance in such situations to ensure human health safety.

Heat Resistance and Cost

Stainless Steel 201 has several other important characteristics that Saigon Horeca has mentioned:

- Heat resistance: has a relatively high heat resistance, ranging from 1,149 degrees Celsius to 1,232 degrees Celsius. This makes it suitable for many applications in high-temperature conditions, such as in the metallurgical industry.

- Cost: Because has a lower nickel content and uses substitutes like manganese and nitrogen, its cost is often lower than Inox 304. This makes Inox 201 an attractive choice for those needing a cost-effective stainless steel material while still ensuring basic properties.

While Inox 201 has a lower cost and relatively high heat resistance, it’s essential to note that its corrosion resistance and heat resistance are still limited compared to some premium stainless steel types. Therefore, when selecting the appropriate stainless steel type for a specific application, careful consideration of technical requirements and working conditions is necessary.

Applications

Inox 201, with its unique characteristics, has created many common and diverse applications in daily life. To harness the full potential of Inox 201 and simultaneously overcome its limitations, we can see that this material is widely used in various fields, including:

- Kitchen Appliances: is often chosen to manufacture food-related products such as spoons, forks, plates, trays, pots, pans, and many other items. The food safety and basic corrosion resistance of Inox 201 make it suitable for contact with food and high temperatures during cooking.

- Interior Decoration: With lower corrosion resistance compared to other stainless steel types, Inox 201 is often used for interior decoration rather than exterior. It is used to create decorative products, entrance doors, kitchen sinks, and many household items.

- Industrial Applications: is also widely used in various industries, including automobile manufacturing, trailers, production of stainless steel sinks, kitchen accessories, manufacturing of auto and motorcycle parts. It is also used in the production of medical equipment and products related to food safety.

With lower corrosion resistance than some premium stainless steel types, Stainless Steel 201 is often prioritized in applications where exposure to harsh environments is not severe. Limiting contact with harsh conditions helps Inox 201 maintain its beauty and durability longer, especially in indoor environments.

Distinguishing Between Inox 201 and Inox 304

Distinguishing between Inox 201 and Inox 304 can be done in several ways. One common method is to check the surface of the product. Inox 304 often has a shinier and more mirror-like surface than Inox 201, while Inox 201 may have a smooth but less shiny surface.

Another way to differentiate is by using specialized steel testing agents. When applying these testing agents, Inox 201 typically produces a brown-red reaction, while Inox 304 often produces a green or colorless reaction.

Additionally, you can also check the chemical composition. By examining the content of elements such as chromium, nickel, manganese, and nitrogen, you can determine whether the sample is Inox 201 or Inox 304.

Depending on the specific intended use and available resources, you can choose the most suitable distinguishing method. However, checking the chemical composition is the most accurate method and does not depend on the sharpness of the observer’s eyes.

>>> To gain a better understanding of the technical advantages and recognize the importance of Inox 304 in ensuring durability and quality for your projects, read on to explore the world of strength and versatility in the application of Stainless Steel 304: Stainless Steel 304 – Durability and Versatile Applications.

Monday - Friday

from 8h00 to 18h00

Số 40 Đường số 6, KDC Melosa Khang Điền, Phú Hữu, HCM.

Contact anytime

In the context of the rapidly growing culinary and food...

Read More