Nội dung bài viết Đọc bài viết với ngôn ngữ Tiếng Việt Hệ thống thông gió bếp I. Overview A […]

Read more

- News

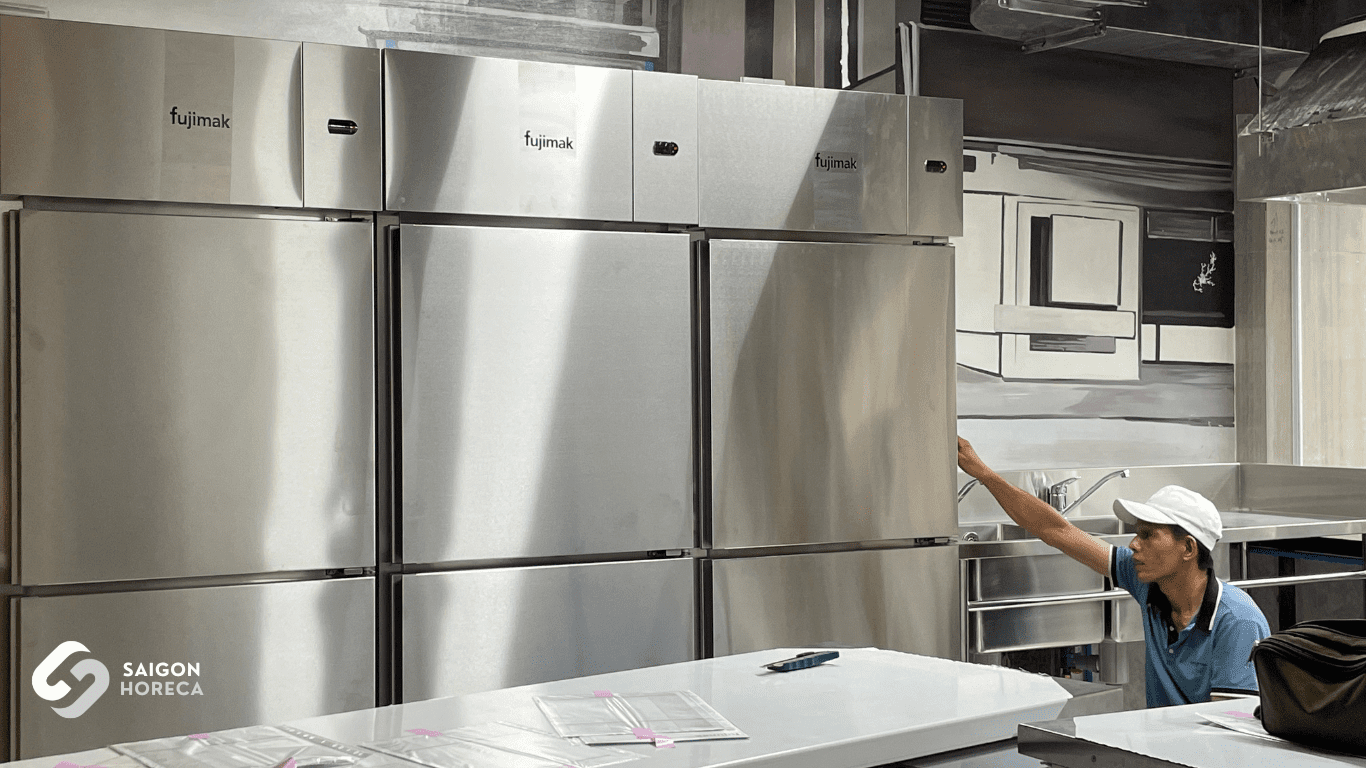

10 common errors when using industrial refrigerators and how to fix them

- May 3, 2025

Industrial refrigerators are not simply food preservation equipment but also the “heart” of every professional kitchen. However, like any other device, industrial refrigerators are not immune to errors that arise during use. Seemingly small problems such as unstable temperatures, unusual noise, or poor refrigeration systems can have major consequences: interrupting work, wasting materials, and even increasing costs operating.

In this article, we will learn about the most common mistakes when using industrial refrigerators, the causes and effective solutions to fix them. This is not only how to protect your device but also the secret to optimizing performance in the kitchen. Let’s get started with Saigon Horeca!

In this Article

Common errors when using industrial refrigerators

The cabinet is not cold enough or not refrigerated

Industrial refrigerators that are not cold enough or even lose their ability to cool are one of the serious errors that directly affect the quality of food preservation. This phenomenon not only disrupts the kitchen’s operating process but also causes food waste and increases operating costs. So, where does the real cause lie?

Popular causes

- Gas leak or gas shortage

Gas refrigeration is “fuel” for the refrigeration system to operate. When there is a leak or shortage, the cooling efficiency is greatly reduced, making the temperature in the cabinet unsatisfactory.

- The cold floor is snowed too much

The heavy snow accumulated on the indoor unit not only hinders the flow of cold air but also increases the load on the system, causing cooling capacity to be impaired.

- Fan or compressor problem

Fans and compressors are the two “brain parts of the refrigeration system. If either malfunctions, the cabinet will not be able to refrigerate effectively.

- Cabinet doors are not closed

Open cabinet doors, due to broken or dirty door seals, will cause cold air to escape, leading to heat loss and making the cabinet less efficient.

How to fix

- Call a professional technician to check the amount of gas in the system and replenish or repair it if a leak is detected. This not only ensures refrigeration but also extends equipment life.

- Snowpacking is a sign of a lack of routine maintenance. Cleaning the indoor unit regularly, removing snow buildup will help improve airflow and optimize cooling performance.

- If the fan or compressor is damaged, replace it with genuine components to ensure stable operation. This should be done by a team of qualified technicians.

- Don’t underestimate the door gasket – this is the protection that keeps the temperature stable inside the cabinet. Clean gaskets periodically and replace them when they are damaged or lose elasticity to ensure the cabinet doors stay closed.

Overcoming the situation of the cabinet not being cold enough or not being refrigerated is not only solving the immediate problem, but also helps to effectively protect the long-term operation of the equipment. A stable industrial refrigerator is the foundation for you to maintain service quality and save operating costs. Therefore, always pay attention to regular maintenance and handle it as soon as you detect unusual signs!

Condenser crash

The condenser is one of the important parts in the refrigeration system, playing the role of converting cold gas from a high pressure state to a liquid state and radiating heat to the outside environment. However, when the condenser crashes, not only is the cooling performance affected but it can also cause damage to the entire system. Below are common problems and detailed fixes.

1. Stop leak

Cause:

Although made from heat-resistant and high-pressure materials such as steel pipes or thick copper pipes, condensers can still leak due to wear and tear over time, mechanical impact, or manufacturing defects. When a leak occurs, the cold gas escapes, preventing the system from maintaining the pressure and temperature required for effective refrigeration.

Handling:

- Visual inspection: Look closely from the cyclone’s push tube to the drying filter, focusing on areas with oil slicks or moisture.

- Using soap bubbles: Here’s how to check accurately and effectively. Spray soap bubbles on the joints or suspected areas, if air bubbles appear, it is the location of the leak.

- Test under operating conditions: When the cyclone is operating, high pressure will make the leak more obvious. Once located, call a technician to repair or replace the condenser if necessary.

2. The condensation is hotter than usual

Cause:

- Insufficient condenser area: When the capacity of the condenser is not commensurate with the cooling capacity of the system, heat is not radiated, causing the condenser to heat up.

- The surface of the condenser collects dust: Dirt accumulated on the condenser surface will reduce heat dissipation, causing the condenser to overload heat.

- Poor air circulation: If the air does not circulate well around the condenser, heat will be trapped, causing unusual heat.

Handling:

- Check the staging area: Make sure the condenser has an area large enough to meet the heat output needs. If not, it needs to be upgraded or replaced with a suitable system.

- Set surface cleaning: Regularly clean the condenser to remove dirt, residue and grease. This not only improves performance but also extends the life of the device.

- Guarantee ventilation: Place the cabinet in a well-ventilated place, avoid placing it too close to walls or other obstructions. Check the cooling fan and make sure the air circulates easily through the condenser.

To ensure the stable operation of the industrial refrigerator, you should check and maintain it periodically, and handle it as soon as you detect unusual signs. Timely action not only saves repair costs but also helps optimize refrigeration performance and prolong equipment life.

Refrigerator makes noise when operating

When industrial refrigerators emit unusual noise, it can not only cause discomfort but can also be a sign of technical problems that need to be overcome soon. Noise usually comes from the following causes and below is the detailed treatment:

1. The storage cabinet is not balanced

Cause:

Refrigerators that are not placed in a balanced position or unstable tripods will cause the cabinet to shake when operating, causing loud noise.

Handling:

- Check the floor surface where the cabinet is located, make sure the floor is flat and not tilted.

- Re-adjust the position of the cabinet so that it is balanced. If necessary, add padding or adjust the height of the tripod to secure the cabinet.

2. The pin pin is dropped or misaligned

Cause:

The machine cyclone pin leg is loose or misaligned from its original position due to vibration during operation, causing unusual noise.

Handling:

- Open the machine block compartment and check the staple pins.

- Use a specialized tool to secure the pin leg in place. If you discover a broken pin pin, replace it to ensure the device operates stably.

3. The engine is dry with grease

Cause:

After a long period of use, the engine, especially the blower motor, may become grease-dried. This not only increases noise but also affects engine life.

Handling:

- Remove the blower motor from the system, pay attention to ensure safety when operating.

- Specialized grease application to rotating shafts and moving parts inside the motor.

- After oiling, reinstall the motor in its original position and check the operation of the cabinet.

Proper identification of the cause and timely handling not only help reduce noise but also ensure the performance and longevity of the equipment. To prevent this condition, you should periodically maintain and inspect important refrigerator parts.

Refrigerator is watery

Drowning industrial refrigerators not only causes inconvenience but can also damage floors and affect business operations. To completely fix it, you need to clearly understand the cause and take appropriate steps.

- Refrigerator water tray is dirty

The drainage hole is clogged due to long-term accumulation of dirt, resulting in water not being able to drain down to the catch tray.

As a result, water spills out and flows to the floor.

- Cracked or punctured water tray

The water tray is damaged, no longer able to hold water, causing water to leak out.

- Water supply pipe broken or loose connection

Water supply pipes have problems, such as leaks or kinks, causing water to flow out of the system.

- Effective fix

Disconnect power

Before doing any operation, unplug the power to ensure safety.

Check the water tray and drain pipe

Take the water tray out to check the condition of the tray. If the tray is dirty, clean it.

Locate the drainage pipe, check if the pipe is clogged or kinked.

Handling:

- If the tube is clogged, use a long soft stick or compressed air to unclog it.

- If the tray is cracked or punctured, replace it with a new tray or use specialized glue to repair it.

Water Supply Pipe Inspection

Make sure the tube does not loosely connect or break. If necessary, replace the tube to ensure stable water circulation.

Contact Warranty Service: In case the cause cannot be determined or cannot be repaired yourself, call a professional warranty worker to ensure correct technical repair.

Routine maintenance tips

- Regularly clean the water tray and check the drainage system to avoid clogging.

- Place the cabinet in a well-ventilated, easily accessible place so that inspection and repair can take place smoothly.

- Perform routine maintenance to reduce the risk of similar incidents.

By timely processing and periodic maintenance, you can ensure the industrial refrigerator operates stably, avoid work interruptions and save on repair costs.

Light but industrial refrigerator not running

When the lights are on but the industrial refrigerator is not running, it is a fairly common situation and needs to be handled quickly to avoid affecting the ability to preserve food. Below are the possible causes of this error and how to fix it:

Cause industrial refrigerators don’t run

- Stop fouling:

- The condenser coil can become dusty, dirty or greasy after a long period of use, reducing cooling efficiency and preventing the refrigerator from running.

- Compressor or temperature regulator relay failure:

- If these parts are damaged, the refrigerator will not be able to operate even if the lights are still on.

How to fix a refrigerator that doesn’t run

- Sanitary condenser:

- Check and clean condenser coils, especially behind or under the refrigerator. Dirt buildup can cause the condenser to stop working poorly, reducing the efficiency of the cabinet.

- Use a soft brush or vacuum cleaner to clean the coil gently.

- Check compressor relays and temperature regulators:

- If after cleaning the condenser the cabinet still does not run, the problem may lie with the compressor relay or the temperature regulator. In this case, you need to call a warranty technician or professional technician for inspection and repair.

Refrigerator Closed in Snow

Snow-covered refrigerators are a common problem, affecting cooling capacity and energy savings. Here are some causes and solutions:

- Contains Too Much Food:

- When the cabinet contains too much food, the space inside the cabinet will be limited, causing the cabinet to operate continuously to maintain a stable temperature. This leads to snowpacking.

- Untight Refrigerator Door Cushion:

- If the cabinet door rubber gasket is damaged or no longer elastic, warm air will penetrate inside, causing the refrigerator to work continuously and leading to snow closing.

How to handle

- Snow Flushing and Cabinet Cleaning:

- First, leave all the food in the refrigerator and let it rest for a while to let the snow melt. Then, clean and clean the indoor unit and snow-stained areas.

- Check Door Pads: -Cabinet door rubber pads check. If a cracked, damaged or loss of elasticity gasket is detected, replace the gasket with a new one to ensure the cabinet door is closed and prevent heat loss.

Advice to prevent the above errors

- Clean parts such as condensers, door pads, and snow-prone areas regularly to ensure the best cooling effect.

- Do not cram too much food in the refrigerator to help air circulate easily and avoid causing snowpack.

By taking these measures, you will help your industrial refrigerator operate efficiently, prolong its life, and minimize unwanted problems.

How to maintain performance and extend industrial refrigerator life

In order for industrial refrigerators to operate stably and sustainably, maintaining performance and extending life is a key factor. Below are effective measures to help you protect your device during use.

3.1. Periodic cleaning

A clean refrigerator not only ensures cooling performance but also prolongs the life of the parts.

Refrigeration and Filters:

- Clean the indoor unit and filter at least once a month to remove dirt and residue that may interfere with heat exchange.

Door Gasket:

- Check and clean door seals regularly to maintain tightness, preventing hot air from getting inside.

3.2. Professional maintenance

In addition to routine cleaning, you should schedule comprehensive inspections and maintenance from professional units.

Machine and Fan Check:

- The engine and fan are important parts that determine cooling performance. Periodic inspections will help to detect signs of wear or damage in a timely manner.

Cold Gas Test:

- Ensure that refrigerated gas levels are always in an optimal state to maintain effective refrigeration.

3.3. Use Properly

Daily usage habits also greatly affect the lifespan of the refrigerator.

Do Not Stuff Foods Excessively:

- Refrigerators need space for cold air to circulate. Over-stuffing of food reduces refrigeration efficiency and puts pressure on the engine vortex.

Closed Cabinet Door:

- Close the cabinet door immediately after picking up food to avoid heat loss and reduce the burden on the refrigeration system.

Proper maintenance not only helps industrial refrigerators operate more efficiently but also significantly saves repair and energy costs. Combine periodic cleaning, professional maintenance and proper use to make the most of the benefits this device offers.

Monday - Friday

from 8h00 to 18h00

40 Street No. 6, Melosa Garden, Phu Huu Ward, Thu Duc, HCMC

Contact anytime

Looking to elevate your grilled dishes with a Salamander Grill? With its ability to grill quickly and evenly while giving […]

Read more